Surface Roughness

What is Surface Roughness?In technical communication, many people are accustomed to using the "surface finish" indicator. In fact, "surface finish" is proposed according to the human visual point of view, while "surface roughness" is proposed according to the actual microscopic geometry of the surface. Because of the need to be in line with the international standard (ISO), the expression term "surface finish" has long been no longer used in the national standard, and the term "surface roughness" should be used for formal and rigorous expressions.

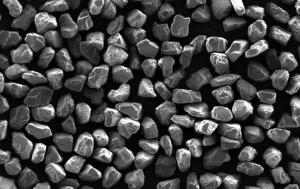

Surface roughness refers to the unevenness of small pitches and tiny peaks and valleys that a machined surface has. The distance (wave distance) between the two peaks or two troughs is very small (below 1mm), which belongs to the microscopic geometric shape error.

Specifically, it refers to the degree of height and distance S of tiny peaks and valleys. Generally divided by S:

S<1mm is the surface roughness

1≤S≤10mm is waviness

S>10mm is f shape

Surface Roughness Forming Factors

Surface roughness is generally formed by the processing method used and other factors, such as the friction between the tool and the surface of the part during processing, the plastic deformation of the surface layer metal when the chips are separated, and the high frequency vibration in the process system, electrical machining discharge pits, etc. Due to the different processing methods and workpiece materials, the depth, density, shape and texture of the traces left on the processed surface are different.