The difference between resin diamond grinding wheel and electroplated diamond grinding wheel

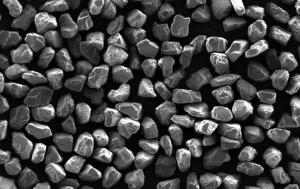

The difference between the resin diamond grinding wheel and the electroplating diamond grinding wheel is the difference in the bonding agent. The resin diamond grinding wheel mainly uses phenolic resin plus a small amount of metal powder as the bonding agent, while the electroplating diamond grinding wheel deposits nickel-cobalt alloy on the surface of the metal substrate by electrodeposition. A grinding wheel production process for fixed diamond abrasives, the main difference in their performance is:1. In terms of processing efficiency, since the electroplated grinding wheel uses higher-grade abrasives and has only one layer of abrasive, it has its own advantages in heat dissipation performance, so the processing efficiency of electroplated diamond grinding wheels is higher;

2. In terms of service life, the electroplated grinding wheel has only one layer of abrasive, so the service life of the electroplated grinding wheel is inferior to that of the resin diamond grinding wheel;

3. In terms of processing accuracy, the impact on the surface roughness of the workpiece, under the same particle size, the surface roughness processed by the electroplated grinding wheel is worse.