hite spots appearing after workpiece grinding

When the workpiece has white spots after grinding, this kind of problem that affects the appearance quality and processing accuracy of the workpiece is relatively common. White spots are visually unattractive and sometimes reveal underlying workmanship issues. So, why does this white spot appear? How to deal with this problem?

The reason for this spotting may be due to three main aspects, one or more of which are mixed, as follows:

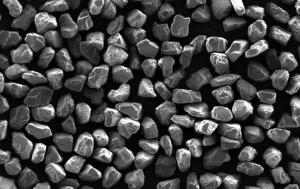

First of all, foreign body adhesion is one of the main reasons that may cause white spots. During the grinding process, foreign matter such as dust in the space, adhered coarse particles, impurities, and fine chips may appear. These foreign matters will affect the grinding effect of the surface and adhere to the surface of the workpiece.

Among them, dust and impurities are common foreign matter in the air, and large-grained abrasive particles are often grinding wheel debris or iron filings and metal scraps that have not been cleaned before processing.

Second, polishing pits can also cause white spots. Due to the tiny surface pits produced by excessive grinding and polishing force, under the action of polishing liquid, the edges of the pits will continue to wear and form white spots. The pits may be due to the fact that the grinding wheel is too thick, and the processing parameters such as the pressure, speed, and feed rate of the grinding wheel are unreasonable. At the same time, the material, hardness, and shape of the workpiece will also affect the appearance of pits.

Finally, raw material defects are the third possible cause of white spots. When third-party grinding companies process silicon wafers in the semiconductor field, it is easy to cause white spots on the surface of the processed silicon wafers due to defects such as cracks and bubbles in the silicon wafer itself.